Molded Power Inductors, combined with the latest industry technology data and quality control points, this guide covers a comprehensive range of content from basic principles, material processes to actual selection and avoidance of pitfalls, making better choices in power supply design.Let’s continue the discussion from the previous article(last time we discuss 6 questions )

7. What is “pressure resistance failure”? (A major problem in selection!)

This is an easily overlooked “hidden pitfall.” There is an insulating layer between the iron powder cores inside the integral molded inductor.

* Issue: In long-term high-voltage, high-frequency operating environments, if the insulation strength is insufficient, the insulation layer between iron powder cores may be punctured.

* Consequence: It is equivalent to connecting a resistor in parallel across the inductor, resulting in a sharp increase in core losses, severe heating, and even chip burnout.

*Avoid pitfalls: In applications where the input voltage exceeds 50V, always confirm the voltage rating of the inductor with the manufacturer, not just the inductance value.

8. What are Isat and Irms? Which one should be considered during selection?

These are two key current parameters:

* Isat (Saturation Current): The current when the inductance drops to a certain proportion (e.g., 30%). Exceeding this value causes a sudden decline in the inductor’s energy storage capability, potentially leading to instability in the power loop.

* Irms (RMS current): The current at which the surface temperature rise of the inductor reaches a specified value (e.g., 40°C), primarily determined by copper loss (DCR).

* Principle: When selecting, both parameters must meet the circuit requirements.

9.Is a lower DCR (DC resistance) always better?

Yes. The lower the DCR, the smaller the copper loss, the higher the power conversion efficiency, and the lower the temperature rise. However, for the same volume, pursuing extremely low DCR typically means a reduced inductance, which requires a trade-off based on the specific application scenario (whether prioritizing high efficiency or large energy storage).

10.How to judge the quality of an inductor ?

A preliminary judgment can be made through the following points:

*Appearance: The surface should be flat and smooth, without burrs or cracks, and the pin coating should be shiny.

*Pin strength: The soldered terminals should be firm and not easily broken.

*Solder resistance: After reflow soldering, the body should not have obvious discoloration or cracks.

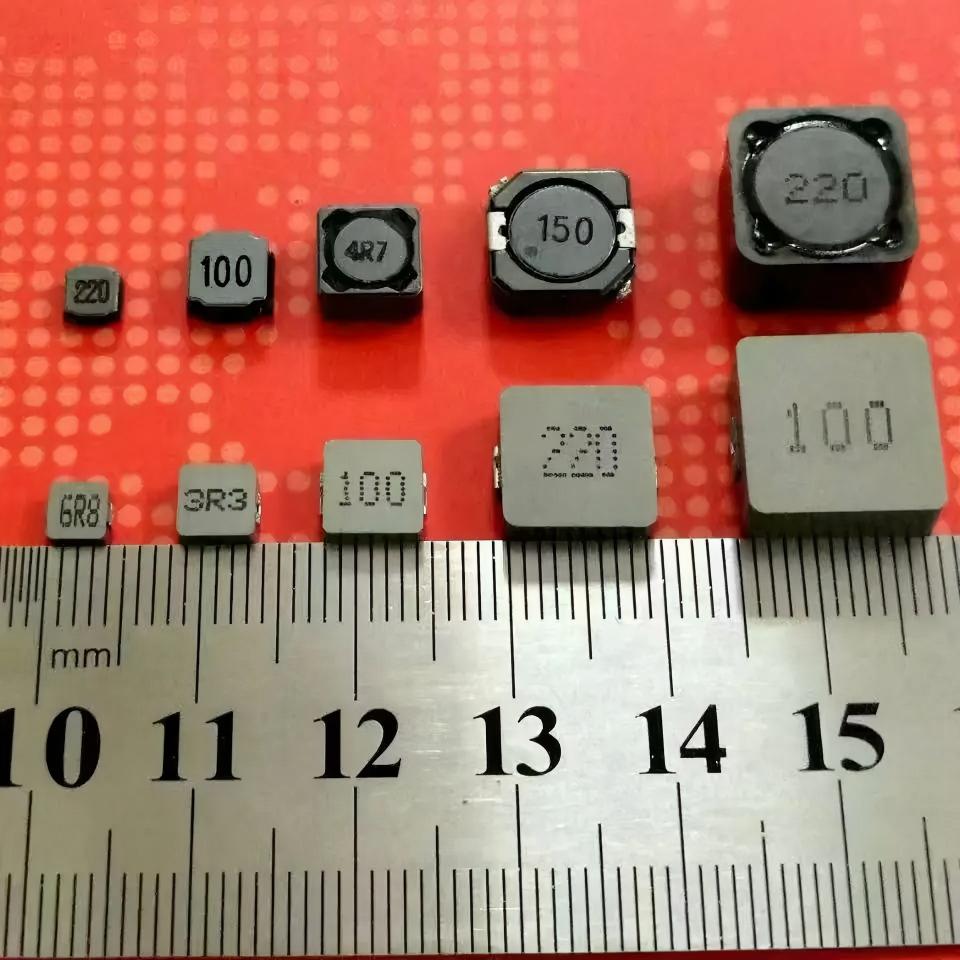

11.Why can integrated inductors be made smaller and thinner?

A: Thanks to powder metallurgy technology, it does not require reserved magnetic core assembly gaps like traditional inductors, and its structure is more compact. At present, technology can achieve ultra-thin products with a thickness of less than 0.5mm, which is very suitable for mobile phones and wearable devices.

12. What is the “T-Core” process?

This is an advanced structural technology that optimizes the magnetic circuit distribution through special molds and winding techniques, further reducing losses and improving high-frequency performance and heat dissipation efficiency.

13. Will the integrated inductor rust?

The raw materials are mostly metal powders. If the insulation coating (such as epoxy resin) on the surface of the product is sprayed unevenly or damaged, there is indeed a risk of oxidation and rusting in high humidity and salt spray environments. High quality fully automatic spraying technology can effectively prevent this problem.

Post time: Feb-02-2026