Molded Power Inductors, combined with the latest industry technology data and quality control points, this guide covers a comprehensive range of content from basic principles, material processes to actual selection and avoidance of pitfalls, making better choices in power supply design.

14. How to address EMI (electromagnetic interference) issues?

The integral molded inductor features a fully enclosed magnetic circuit structure with minimal leakage flux, inherently possessing excellent anti-interference capabilities. If interference still occurs in the circuit, it is typically due to layout and routing issues rather than the inductor itself.

15. Is there a gap / big difference between domestic and imported (e.g., Vishay, TDK) products?

In the past, overseas manufacturers (American and Japanese) dominated the market, but in the mid-to-low-end and some high-end segments, domestic manufacturers have achieved technological breakthroughs and mass production, offering significant cost-performance advantages.

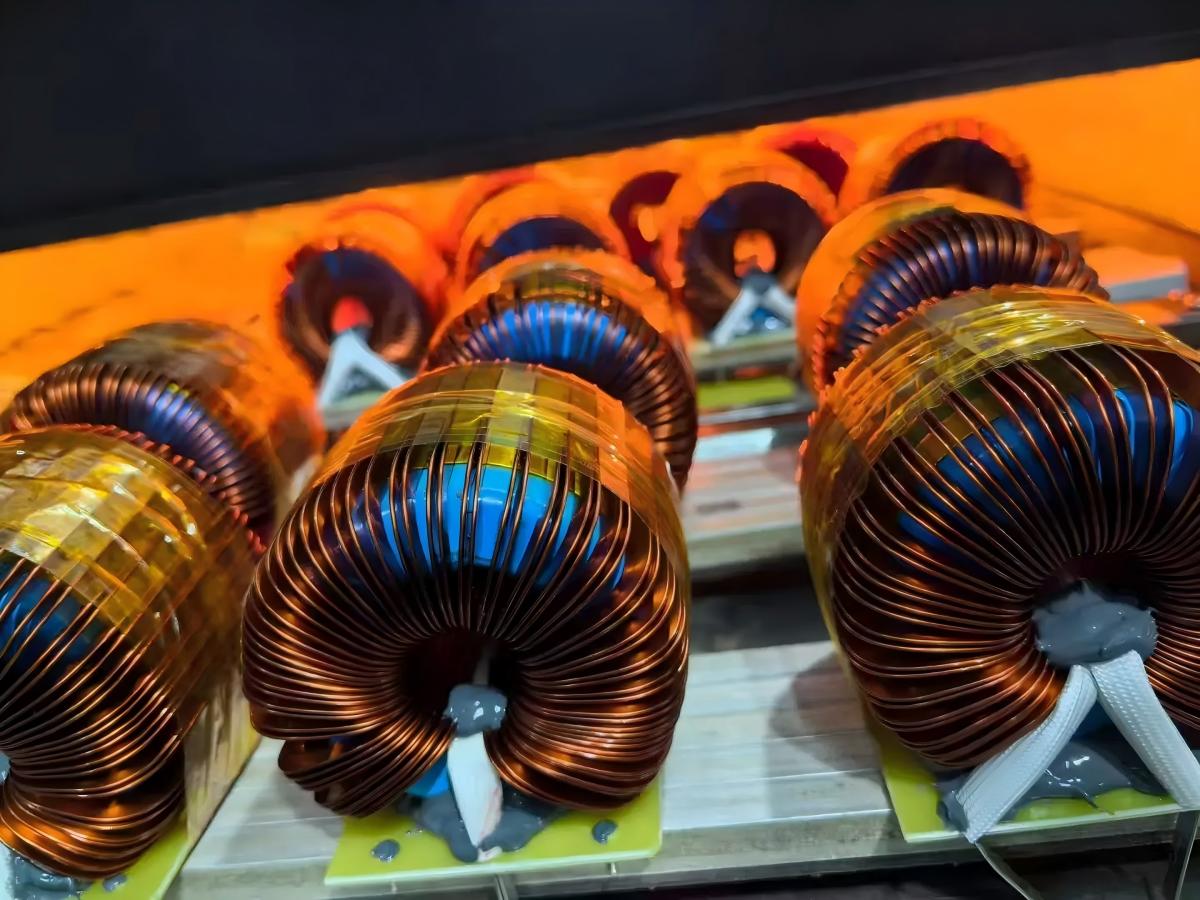

For exacmple ![]() ur High-current thermal compression integrated inductor MSY series

ur High-current thermal compression integrated inductor MSY series

Such as MPS PN: MPL-AL6050-5R6 , you can use our COILMX PN:MSY6050-5R6M,with

ultra-high current thermal press integrated inductor, can Completely replacing the American wire-wound coil manufacturer Coilcraft XGL/XEL/XAL/XFL series, also can Completely replacing the American MPS MPL-AL Series,we adopts the T-Core flat cable design,with self-developed unique powder formula,using ultra-low-pressure hot pressing technology,achieve the performance of a traditional cold-pressed integrated inductor of the same volume,DCR is half the size, yet the saturation current is double the effect!

Such MPS PN: MPL-AL6060-150 , can use our COIL MX PN:MSY6060-150M Inductance: 15 microhenrys DCR internal resistance: 35 milliohms,Irms temperature rise current: 5.8A Isat saturation current: 5.5A

16.What is AEC-Q200 certification?

This is the stress testing standard for automotive electronic components. If an inductor is nominally used in automotive electronics, it must pass this certification to ensure reliable operation under extreme temperatures, vibrations, and humidity conditions.

17. Is the heating of the inductor normal?

As long as the temperature rise is within the range specified in the datasheet (typically around 40°C corresponding to Irms), it is considered normal. If abnormal heating occurs, it is usually due to a mismatch between the circuit operating frequency and inductor characteristics, or a “insulation breakdown” failure as mentioned earlier.

18. How to conduct incoming material inspection?

Routine inspections include: visual inspection, dimensional measurement, sensitivity (L) testing, DCR testing, withstand voltage testing (Hi-Pot), and solderability testing.

19. Is burn-in testing necessary?

It is highly necessary. High-temperature aging tests can identify products with early failures (such as internal microcracks or insulation defects), thereby enhancing the long-term reliability of batch usage.

20. What are the future development trends?

Two directions: one is ultra-thinning (<0.5mm) to adapt to wearable devices; the other is ultra-high power density, achieved through material formulation upgrades (such as nanocrystalline composites) to reduce losses, meeting the high-efficiency demands of AI servers and new energy vehicles.

Summary:recently we discussed 20 questions about the inductor , in the future follow us for more professional information !we have 20 years experience for the inductor ,if u have any question , you can also send to my mailbox :[email protected],thank you !

Post time: Feb-06-2026