1)Common Amorphous Materials for AI Server Magnetic Components

A core amorphous material system: Fe-based amorphous soft magnetic ribbon and powder (Fe–Si–B system): Based on rapidly quenched ribbons, the typical composition is Fe73.5Si13.5B9Cu1 (FINEMET), along with variants such as Fe–Si–B–C and Fe–Si–B–Cr. Characteristics include high resistivity, low coercivity, and low hysteresis/eddy current losses, making it suitable for high-frequency low-loss applications such as EMI common-mode inductors, PFC inductors, and isolation transformers. The powder form can be prepared through atomization (gas/water/gas-water combined) for subsequent pressing and forming.

Fe-Co-based amorphous alloys, such as the Fe-Co-B-Si-Nb system, exhibit extremely high saturation magnetization (up to approximately 1.9 T) and very low coercivity. They offer advantages in applications requiring both high magnetic flux density (Bs) and low high-frequency losses (e.g., high-end common-mode/differential-mode cores and power inductors), but their cost and brittleness must be carefully balanced.

Co based amorphous alloys, such as the Co-Fe-B-Si system, are characterized by ultra-high initial magnetic permeability (up to the order of 10 ^ 5) and broadband impedance characteristics, making them ideal for common mode noise suppression in the range of 150 kHz to 30 MHz. They are commonly used in EMI input/output filtering for server power supplies.

Fe based amorphous/nanocrystalline composites and bulk metallic glass (BMG): Bulk or composite magnetic cores are prepared through processes such as powder metallurgy and SPS (discharge plasma sintering), taking into account high density, complex shape, and low loss characteristics; The FeSiBCCr and other amorphous systems studied exhibit excellent soft magnetic properties and process feasibility, making them suitable for exploring the application of integrated inductors and high-power density magnetic components.

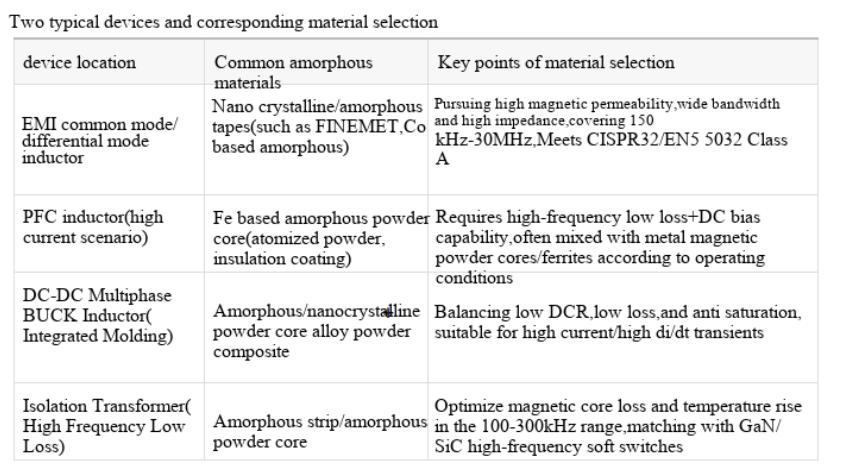

2) typical devices and corresponding material selection

The above correspondence reflects the overall pattern of “front-end amorphous/nanocrystalline+back-end ferrite” for AI server power supply, as well as the preference trend of integrated inductors for amorphous/nanocrystalline powder cores.

3) points for engineering selection

frequency and loss: mainstream designs use 90-120 kHz as the mass production benchmark, and strict control of magnetic core and copper loss is required when testing up to 200-300 kHz; Amorphous materials have advantages in high-frequency and low loss areas, but they need to be evaluated in conjunction with specific B-H curves and temperature rise margins.

DC bias and saturation: Pay attention to the saturation magnetic flux density (Bs) and DC superposition characteristics of materials at 100-120 ℃, to avoid sudden drops in inductance and uncontrolled temperature rise under high temperature conditions.

Process and reliability: Amorphous powders require insulation/coating and densification processes (such as SPS) to balance resistivity, loss, mechanical strength, and thermal stability; Mass production stability and consistency are key thresholds. Typical application of amorphous materials in AI server power supply High frequency isolation transformer and high-frequency inductance of SST solid-state transformer

In the AIDC power supply chain from 800 V HVDC to 48/12 V, SST achieves high efficiency and miniaturization through high-frequency isolation and bidirectional energy control. Under high-frequency conditions, the core loss of amorphous/nanocrystalline magnetic cores can be reduced by about 60% -80% compared to traditional silicon steel sheets, and the overall efficiency can reach 98%+. It also significantly reduces the volume of transformers and magnetic devices, making it suitable for MW level modular SST systems (such as Delta’s solution).

Post time: Jan-05-2026